Lifting Equipment Suppliers

Manufacturing Method, Features, Advantages, Usage Methods, How to Choose the Product and Conclusion.

Lifting gear suppl pallet jack iers, lifting equipment providers, and material handling equipment suppliers play a crucial role in various industries. They offer an extensive range of lifting equipment that is vital for improving efficiency and safety in workplace operations. Lifting equipment suppliers provide solutions designed to handle heavy loads with ea pallet jack se while ensuring the safety of workers.

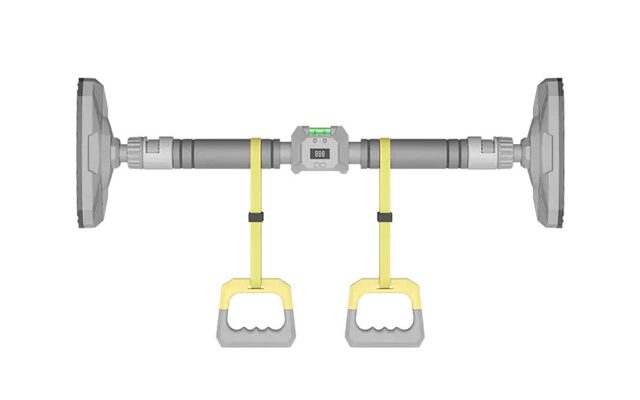

One of the most common types of lifting equipment is a pallet jack. Pallet jacks are essential tools used to lift and transport pallets or skids within warehouses or factories. These versatile devices can be manually operated or powered by electricity. Their compact design allows them to maneuver through narrow aisles easily.

Manufacturing methods for lifting equipment vary depending on the type and complexity of the device. However, most reputable lifting gear suppliers follow standardiz Lifting gear suppliers ed manufacturing processes that adhere to quality standards and regulations. Advanced technologies such as computer-aided design (CAD) software are utilized to cre Lifting Equipment Suppliers ate precise specifications before production begins.

The features of lifting equipment can differ based on their specific applications but typically include robust construction, ergonomic designs for operator comfort, intuitive controls for easy operation, adjustable settings for different load sizes and weights. Many modern models also incorporate advanced safety features like overload protection systems and emergency stop butto Lifting Equipment Suppliers ns.

When it comes to advantages offered by lifting equipment suppliers’ products over traditional manual labor methods:

1) Improved Efficiency: Lifting devices greatly reduce manual effort required when moving heavy objects. This leads to increased productivity as tasks can be completed faster.

2) Enhanced Safety: By using proper lifting gear supplied by trusted manufacturers, worke

rs can minimize their exposure to physical strain injuries caused by repetitive motions or excessive weight bearing.

3) Versatility: There are available options suitable for different indus

tries ranging from healthcare facilities requiring patient lifts; construction sites needing crane systems; warehouses relying on overhead hoists etc.

4) Cost Savings: Investing in quality lifting equipment supersedes the long-term cost of injuries, downtime, and damaged goods associated with ma Material handling equipment suppliers nual handling.

To use lifting equipment effectively, operators should receive proper training on its operation and safety guidelines. The manufacturer typically provides manuals or educational resources to ensure safe usage.

When selecting a suitable product from lifting equipment suppliers for specific needs, several factors should be considered:

1) Load Capacity: It’s crucial to choose a lifting dev Lifting equipment providers ice that can handle the intended weight without risking damage or accidents.

2) Size and Dimensions: Consider the available space where the equipment will operate to ensure compatibility.

3) Durability: Look for products made from high-quality materials that withstand heavy use under different conditions.

4) Maintenance Requirements: Understand any additional maintenance needed for optimal performance. Choose devices with accessible spare parts and reliable after-sales s Lifting Equipment Suppliers upport.

In conclusion, Lifting Equipment Suppliers play a critical role in provid Lifting Equipment Suppliers ing various solutions such as pallet jacks designed to enhance efficiency while ensuring worker safety. Their extensive range of options cater to diverse industry needs through standardized manufacturing methods that result in features like robust construction, ergonomic designs, adjustable settings for load

sizes/weights along with advanced safety systems. By choosing suitable products based on load capacity; size/dimensions; durability & maintenance requirements businesses optimize their operations by reducing labor intensity/risks while increasing overall productivity leading towards achieving desired goals successfully.