Walkie Stacker: An Efficient Solution for Material Handling

Introduction:

In today’s fast-paced industrial worl Electric walkie stacker d, material handling plays a vital role in ensuring smooth operations within warehouses and distribution centers. One such equipment that has revolutionized the industry is the walkie stacker. This article will delve into the manufacturing process, features, advantages, usage methods, tips for selecting this product, and conclu rigging supplies de with its significance in modern-day logistics.

Manufacturing Process:

The walkie stacker is manufactured using state-of-the-art technology to ensure precision and durability. Each component undergoes strict quality control measures to meet industry standards. The key stages of manufacturing include designing the frame structure, assembling mechanical parts such as hydraulic systems and motors, incorporating ergonomic features for user comfort, and conducting thorough testing before packaging.

Features:

1. Walk-behind Forklift: A walkie stacker functions as a compact vehicle that can be operated by an individual walking alongsi walkie stacker de it.

2. Electric Walkie Stacker: Powered by electricity instead of conventional fuel sources.

3. Pallet Stacker: Designed specifically for lifting and transporting pallets efficiently.

Advantages:

1. Versatile App Pallet stacker lication: Walkie stackers are suitable for a wide range of industries including warehousing, manufacturing facilities, retail stores, and more.

2. Space Optimization: These machines are built with narrow dimensions which make them ideal for navigating tight spaces like aisles without causing damage to surroundings or inventory.

3.Cost walkie stacker -Effective Solutions:Electric models eliminate the need for expensive fossil fuels while also reducing maintenance costs compared to traditional combustion engines.

Usage Methods:

To utilize a walkie stacker effectively,

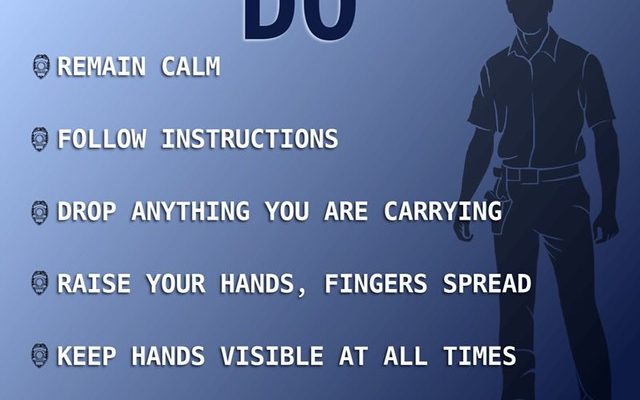

1. Safety First – Operators should receive proper training regarding how to operate equipment safely.

2.Pallet Placement – Ensure careful positioning of pallets on forks before raising or lowering loads.

3.Weight Distribution – Distribute weight evenly across the forks while stacking materials to prevent imbalances or tipp rigging supplies ing hazards.

How to Select the Right Walkie Stacker:

1. Lift Capacity: Consider the maximum weight that needs to be handled regularly.

2. Height Requirements: Determine the maximum height of stor

age forklifts need to reach within your facility.

3. Battery Life: Evaluate battery runtime and charging duration to ensure uninterrupted operation throughout work shifts.

4. Maneuverability: Assess the turning radius and ease of control offered by different models.

Conclusion:

In conclusion, the walkie stacker has become an indispensable tool in material walkie stacker handling operations due to its manufacturing quality, key features like being a walk-behind forklift, electric power source, and suitability for pallet stacking. Its numerous advantages including versatility, space optimization, and cost-effectiveness contribute significantly to enhancing overall efficiency in warehouses. A thorough understanding of usage methods enables operators to utilize this equipment safely while selecti Walk-behind forklift ng the right model considering lift capacity, height requirements, battery life expectancy, and maneuverability ensur walkie stacker es optimal performance tailored according to specific operational needs. Embracing walkie stackers proves crucial in streamlining logistics processes while ensuring prompt delivery of goods worldwide.

Keywords: Walkie stacker; Walk-behind forklift; Electric walkie stacker; Pallet stacker; Rigging supplies

Reference:

(Images sourced from www.pixabay.com)