Title: Industrial Dust Collector: Efficient and Safe Air Pollution Control Device

Introduction to Industrial Dust Collectors

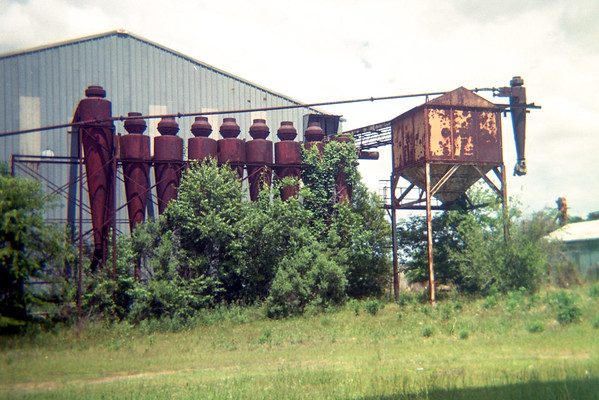

Industrial dust collectors, also known as particulate matter collectors or particle removal INDUSTRIAL DUST COLLECTOR systems, are essential equipment used in various industries for effective air pollution control. These devices efficiently remove harmful particles from the air, ensuring a clean and safe working environment. In this article, we will explore the manufacturing process of industrial dust collectors, their characteristics, advantages, usage methods, how to select the right product for your needs, and conclude with a summary.

Manufacturing Proce Dust filtration unit ss:

The production of industrial dust collectors involves several steps. First, high-quality materials that can withstand harsh industrial environments are selected. These materials include heavy-duty metals such as stainless steel or carb Fume extraction system on fiber reinforced plastic (CFRP).

Next is the assembly stage where various components like filters, fans or blowers for suctioning air into the system are integrated. The filters play a vital role in capturing particles while allowing clean air to pass through effortlessly.

During the engineering phase of manufacturing these units; safety measures take precedence due to their importance in maintaining workplace health and avoiding acc

idents related to exposure to hazardous substances.

Characteristics:

Industrial dust collectors exhibit several crucial characteristics that make them effective at controlling air pollution:

1. High Filtration Efficiency: Utilizing advanced filtration technology ensures efficient capture and retention of even tiny airborne particl INDUSTRIAL DUST COLLECTOR es.

2. Low Air Pressure Drop: Carefully designed airflow pathways reduce resistance within the collector system resulting in improved energy efficiency.

3.Robust Design:

i.Explosion-Proof Construction: Explosion-proof dust removal equipment is specially designed with additional safety features such as spark arrestors and explosion vents to mitigate potential risks associated with combustibl explosion-proof dustremoval equipment e materials.

ii.Noise Reduction Technology:Incorporating noise reduction techniques helps maintain lower noise levels during operation without compromising performance efficiency.

Advantages:

Investing in an industrial dust collector provides numerous benefits for both businesses and personnel:

1. Workplace Safet

y: Eliminating harmful particles from the air safeguards workers’ health by reducing exposure to toxins and preventing respiratory issues.

2.Cost Savings: Effective filtration minimizes the deposition of dust particles on machinery and equipment, resulting in lower maintenance costs and a longer lifespan for these assets.

3.Environmental Compliance:Using industrial dust collectors aids in meeting regulatory requirements regarding air quality standards, ensuring compliance with environmental regulations.

Usage Methods:

Industrial dust collectors are typically installed at various stages throughout manufacturing processes or strategically placed near sources where particulate matter is produced. Common application areas include welding w INDUSTRIAL DUST COLLECTOR orkshops, chemical plants, pharmaceutic INDUSTRIAL DUST COLLECTOR al industries, woodworking shops, food processing facilities, and many more. The units come in different sizes accommodating specific operational needs.

How to Select the Right Product:

Choosing an appropriate industrial dust collector requires considering several factors:

1.Airflow Requirements: Determining the required volume of airflow ensures efficient collection and removal of contaminants.

2.Particulate Matter

Composition: Identifying particle characteristics such as size, material composition helps select filters suitable for capturing them effectively.

3.Explosion Hazard Risks:For environments with explosion hazards or dealing with combustible materials; opting for explosion-proof models becomes essential.

4.System Maintenance Considerations: Assessing filter replacement frequency,

cleaning procedures complexity ease plays an important role in avoiding prolonged system downtime due to maintenance activities.

Conclusion:

Industrial Dust Collectors are crucial devices for protecting worker’s health while maintaining clean air quality wi INDUSTRIAL DUST COLLECTOR thin workplaces. These highly efficient pollution control systems offer numerous advantages including cost savings through reduced equipment maintenance expenses as well as compliance with environmental regulations. By understanding their manufacturing process, distinctive features,advantages,usage methods,and key considerations when selecting these products; businesses can make informed choices ens Air pollution control device uring optimal performance tailored to their unique industrial settings