Waterproof Wiring Connectors: Ensuring Reliable Electrical Connect waterproof wiring connectors ions

Introduction:

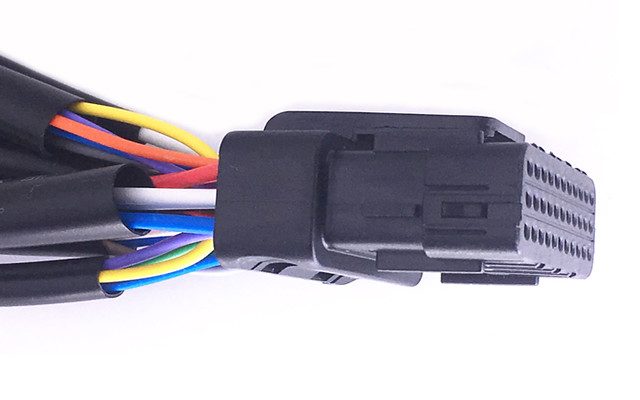

Waterproof wiring connectors have become an essential component in various industries where electrical connections are exposed to moisture, water, or other challenging environmental conditions. In this article, we will explore the manufacturing process, features, advantages, usage methods, tips for selecting these connectors and conclude with their importance in en waterproof low-voltage wire connectors supplier suring reliable electrical connections.

Manufacturing Process:

Manufacturers employ advanced techniques to produce waterproof wiring connectors. These connectors are carefully constructed using high-quality materials such as silicone rubber or thermoplastic elastomer which provide excellent resistance against wat

er and corrosive substances. The manufacturing process involves precision molding and sealing technology to achieve a watertight seal.

Features:

– Waterproof Cable Connectors: Designed specifically for outdoor applications where cables need protection from rainwater or direct exposure.

– Damp-proof Wire Terminals: Offer superior moisture resistance preventing any potential damage caused by condensation or humidity.

– Immersion-gra Waterproof cable connectors de Wiring Connectors: Withstand complete immersion under specific depths of water without compromising their functionality.

–

Liquid-tight Electrical Joints: Provide a secure connection even when subjected to pressurized liquid environments.

– Rainproof Electrical Connectors: Ensure consistent performance during heavy rainfall scenarios.

Advantages:

The use of waterproof wiring connectors offers numerous advantages compared to regular connectors:

1. Enhanced Safety: By preventing water ingress into electrical connections, these connectors significantly reduce the risk of short circuits and electrocution hazards in wet environments.

2. Increased Durability: These specialized connectors are manufactured using robust materials that can withstand harsh weather condit waterproof low-voltage wire connectors company ions like extreme temperatures, UV radiation, chemicals waterproof wiring connectors supplier and prolonged exposure to moisture – making them highly durable.

3. Reliable Performance: Waterproofing ensures uninterrupted connectivity even in damp surroundings; thus guaranteeing continuous operation of critical electronic systems regardless of external factors.

Usage Methods:

Using waterproof wiring connectors is straightforward:

1. Prepare the Wires: Strip off sufficient insulation on both wires to expose the conductive cores.

2. Insert Wires into Connectors: Carefully insert the stripped ends of the wires into appropriate connector sl waterproof wiring connectors ots, ensuring a snug fit.

3. Tighten and Seal: Utilize tightening screws or clamps provided with connectors to secure and ensure a tight seal between wires and connectors.

How to Select Waterproof Wiring Connectors:

Consider the following factors when selecting waterproof wiring connectors:

1. Environmental Exposure: Determine whet

her you require connectors for outdoor, indoor-wet, or submerged applications. Each scenario deman Immersion-grade wiring connectors ds different types of waterproofing attributes.

2. Voltage Rating: Ensure that connectors are compatible with your specific voltage requirements to avoid any potential electrical issues.

3. Wire Diameter Compatibility: Verify that the chosen connectors can accommodate your wire sizes adequately without compromising connection quality or safety standards.

Conclusion:

Waterproof wiring connectors play an indispensable role in safeguarding electrical connections from water damage, humidity, and other challenging conditions. Their use offe waterproof wiring connectors rs enhanced safety levels, durability, and reliable performance in various industries such as marine operations, outdoor lighting systems, HVAC units and more. By carefully selecting these connectors based on application-specific re Damp-proof wire terminals quirements outlined above; one can ensure long-term reliability and optimal functionality of critical electronic systems even in harsh environmental conditions.