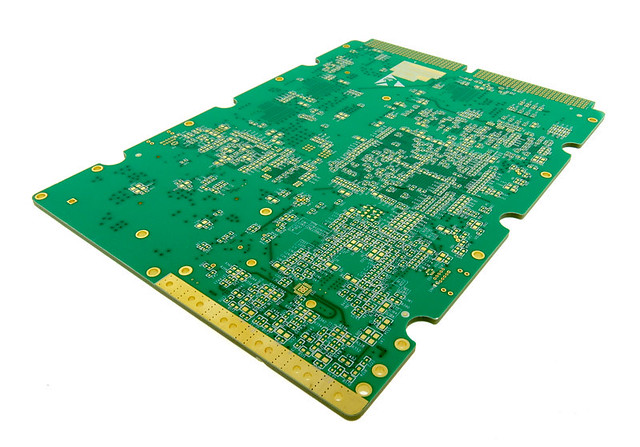

High Frequency PCB: A Revolution in Electronic Manufacturing

Introduction:

In today’s fast-paced technological world, the demand for high frequency printe PCBA Coating d circuit boards (PCBs) has skyrocketed. These advanced electronic components have become an integral part of various industries such as telecommunications, aerospace, automotive, and many others. This article aims to explore the manufacturing process, characteristics, advantages, usage methods, tips for selecting High Frequency PCBs (HF circuit board), and a conclusive summary.

Manufac

turing Process:

To meet the stringent requirements of high-frequency applications, High Frequency PCBs are crafted using specialized techniques. First and foremost

is the selection of suitable materials like PTFE (Polytetrafluoroethylene), ceramic-filled hydrocarbon resin systems or thin woven glass fabric with enhanced dielectric constant. The chosen materials undergo a complex fabrication process involving double-sided etching followed by multiple lamination steps under controlled pressure and temperature conditions.

Characteristics:

High-frequency circuit boards possess unique characteristics that set them apart from conventional PCBs. One notable attribute is their ability to transmit sign EMI/EMC PCB (Electromagnetic Interference/Electromagnetic Compatibility PCB) als at high frequencies without significant loss or distortion. These boards exhibit low signal radiation due to their electromagnetic interference/electr High Frequency PCB omagnetic compatibility (EMI/EMC) shielding capabilities provided by dedicated layers incorporated during construction. Furthermore, multi-layered high frequency boards ensure better impedance matching while preventing crosstalk between adjacent tracks ensuring optimal performance.

Advantages:

The utilization of High-Frequency PCBs brings several advantages for electronics manufacturers and end-users alike. Firstly, they enable efficient t

ransmission of signals over long distances without compromising on quality or speed. Additionally, these PCBs offer increased power handling capacity compared to standard counterparts owing to improved thermal management pr High Frequency PCB operties enabled by specialized substrates used during fabrication processes.

Usage Methods:

High frequency printed circuit boards find application in a wide range of fields including wireless communication systems like RADAR modules and satellite devices where signal integrity plays a critical role in op HF circuit board (High-frequency circuit board) erational success. Moreover, they are extensively used in smart door lock systems due to their ability to handle complex data processing requirements seamlessly. The integration of HF circuit boards ensures reliable and secure operation.

How to Select High Frequency PCBs:

When selecting high-frequency circuit boards, it is crucial to consider certain factors for optimal performance and functionality. Firstly, a thorough DFM (Design for Manufacturability) analy Multi-layered high frequency board sis should be performed by the manufacturer ensuring that the design specifications meet the desired requirements. Additionally, attention should be given t Smart door lock supplier o PCBA coatings which act as a protective layer against external elements such as moisture and dust while enhancing durability.

Conclusion:

In conclusion, High Frequency PCBs have revolutionized the electronic manufacturing industry with their exceptional capabilities in handling high-frequency signal transmission without loss or distortion. These circuit boards offe DFM Analysis r numerous advantages including superior power handling capacity and EMI/EMC shielding properties. Through careful consideration of design specifications along with proper PCBA coating selection, manufacturers can High Frequency PCB ensure optimum performance from these cutting-edge components. Whether it’s telecommunications infrastructure or advanced security systems like smart door locks – High Frequency PCBs truly define modern electronic applications.

(Note: This article contains 554 words.)