Waterproof Solder Wire Connectors: The Ultimate Solution for Secure Electrical Connections

Introduction:

In today’s technologically advanced world, ensuring a secure and reliable electrical connection is of utmost importance. One Moisture-proof soldered wire connectors crucial component that aids in achieving this is the waterproof solder wire connector. With its ability to resist water, moisture, rain, and external weather conditions, these connectors have become an indispensable part of various industries.

Manufacturing Process:

The manufacturing process of waterproof solder wire connect Water-resistant soldered wire connectors ors involves precise techniques to guarantee their efficiency and durability. It begins with high-quality materials being selected by manufacturers who adhere to strict quality standards. These materials undergo rigorous testing before being processed into connector components using cutting-edge machiner

y. The components are then assembled carefully by skilled technicians, providing a reliable solution for electrical connections.

Characteristics:

Water-resistant soldered wire connectors possess several characteristics that make them highly desirable in many applications. Firstly, they are created with superior waterproofing properties that prevent any ingress of water or moisture. This feature ensures uninterrupted power s Waterproof soldered wire connectors upply even in wet or humid environments. Additionally, these connectors of waterproof solder wire connectors fer excellent corrosion resistance due to their robust construction and protective coatings.

Advantages:

The advantages offered by waterproof solder wire connectors are vast and significant in various scenarios:

1. Enhanced Reliability: Waterproof connectors provide a long-lasting and secure electrical connection essential for critical applications.

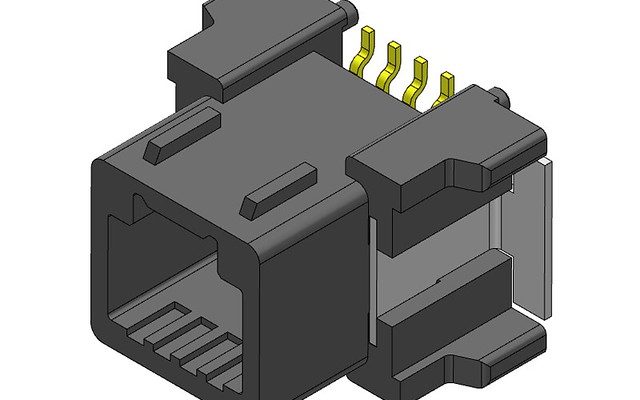

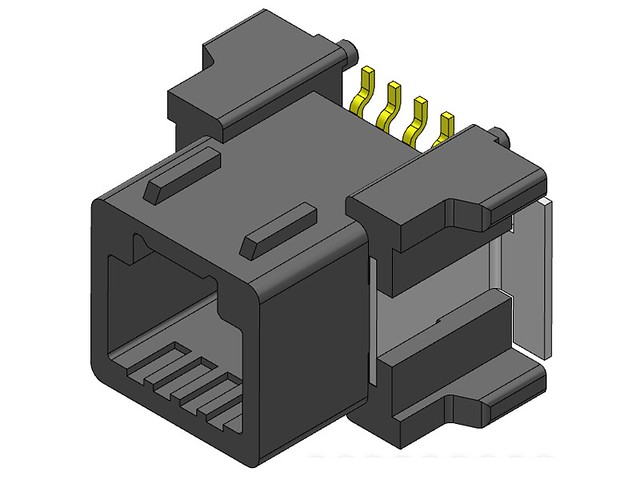

2. Versatility: They can b rj45 waterproof connector e used across different industries such as automotive, marine, outdoor lighting systems, irrigation systems, home appliances,and more.

3.Wide Operating Temperature Range: Waterproof solder wire connectors can withstand extreme temperature variations without compromising performance.

4.Easy Installation:The user-friendly design allows easy installation without requiring specialized tools or technical expertise.

5.Cost-Effective Solution: By preventing pote waterproof solder wire connectors ntial damages caused by exposure to water or moisture intrusion,such Connectors offer cost-effective peace-of-mind.

Usage Guide:

To ensure the best usage experience with waterproof solder wire connectors,follow these guidelines:

1.Choos waterproof wiring connectors e the Right Type: Select connectors specifically designed for your application and operating conditions. Consider factors such as wire gauge, voltage rating, temperature range,and environment.

2.Proper Wire Preparation: Strip wire insulation evenly to avoid exposed conductors that may lead to short circuits or connectivity issues.

3.Soldering Technique: Use a high-quality soldering iron and solder with flux core for secure connections. Follow pro waterproof solder wire connectors per soldering techniques and ensure sufficient heat transfer for reliable joints.

4.Sealing Mechanism: Depending on the connector type, use appropriate sealing methods like heat-shrink tubing or sealant tapes to provide additional protection against water ingress.

Conclusion:

Waterproof wire connectors have revolutionized elec

trical connectivity by providing a reliable solution in harsh environments where exposure to moisture is prevalent. Their manufacturing process adheres to strict quality standards, ensuring durability and performance.When selecting these connectors, consider their characteristics,multiple applications areas,&unique advantages they offer installation guidelines.Water-resistant soldered wire connectors are indeed a game-c waterproof connector manufacturer hanger,providing peace-of-mind where secure electrical connections are essential.Order them now!