Title: The Ultimate Guide to Waterproof Wiring Connectors

Waterproof wiring connectors are a crucial component in various electrical a Waterproof cable connectors pplications, ensuring a secure and reliable connection even in the harshest conditions. Weatherproof electrical connectors, waterproof cable connectors, and damp-proof wire terminals are all essential for protecting electr Weatherproof electrical connectors ical connections from moisture and corrosion. However, when it comes to superior waterproofing capabilities, nothing beats waterproof wiring connectors.

Manufacturing Process:

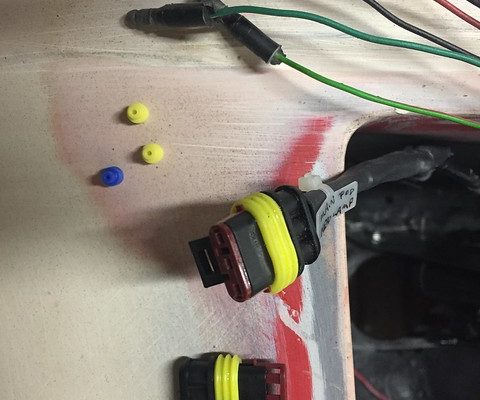

Waterproof wiring connectors are typically made using high-quality materials such as silicone or rubber that offer excellent resistance to water infiltration. These materials are molded into durable connector bodies that provide a tight seal around the wires waterproof bulkhead connector , preventing any water or moisture from seeping in.

Features:

The key feature of waterproof wiring connectors is their ability to maintain a watertight seal even when submerged underwater. This makes them ideal for outdoor applications where exposure to rain, snow, or humidity is unavoidabl Damp-proof wire terminals e. Additionally, these connectors often come with insulation displacement technology that ensures a solid connection without the need for soldering.

Advantages:

One of the main adva waterproof wiring connectors ntages of waterproof wiring connectors is their durability and longevity. Unlike traditional wire nuts or tape that can degrade over time, these connectors offer long-lasting protection against moisture-related damage. They also simplify installa waterproof wiring connectors tion by eliminating the need for additional sealing methods.

Usage:

To use waterproof wiring connectors effectively, start by preparing the wires – strip off the insulation and twist together stranded wires if needed. Then simply insert the wired ends into each side of the connector until they reach the stop point. Finally, close the connector securely to ensure a tight seal.

How to Choose:

When selecting wat waterproof wiring connectors erproof wiring connectors for your project, consider factors such as temperature rating, voltage capacity, and environmental conditions. Opt for reputable brands like waterproof connector manufacturers that adhere to strict quality standards and offer warranties on their products.

Conclusion:

I waterproof light socket n conclusion,

waterproof wiring

connectors are essential components for any outdoor or wet environment electrical installation.

Their superior sealing properties,

durable construction,

and ease of use make them an excellent choice

for safeguarding your electrical connections against water waterproof connector manufacturer damage.

By following this guide

on manufacturing

processes,

features,

advantages,

usage methods,

and selection criteria

for

wat

erproof wiring

connectors,

you can ensure reliable performance and peace of mind knowing your connections are well-protected from moisture.

Choose wisely and invest in quality waterproof solutions today!