Title: The Power of HDI PCBs in Modern Electronics

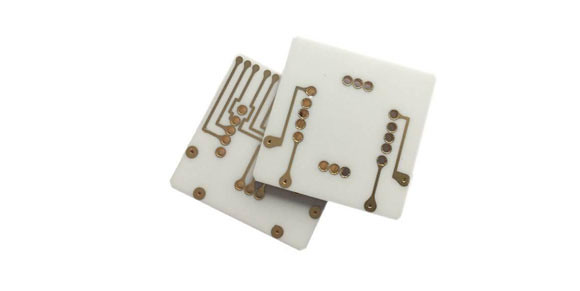

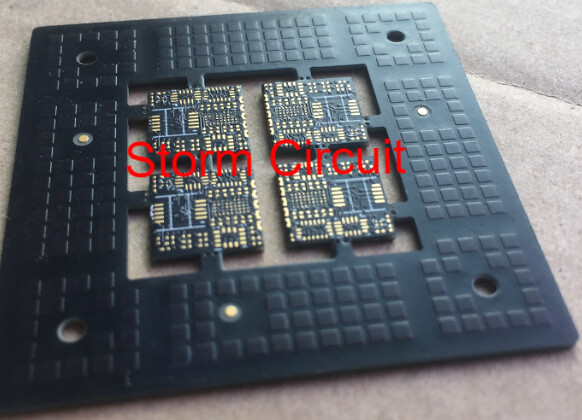

In the fast-paced world of electronics, the demand for hi Multilayer PCB gh-performance and compact devices is ever-increasing. This has led to the rise of Complex Layered Printed Circuit Boards (CLPCB) such as HDI PC High-density interstitial copper-embedded PCB Bs, which have become essential components in many electronic products. HDI printed circuit boards are desig HDI PCB ned with High-density interstitial copper-embedded technology, allowing for a higher wiring density and finer lines and spaces.

HDI PCBs are manufactured using advanced techniques that involve multiple layers of co Complex Layered Printed Circuit Board (CLPCB) pper interconnections stacked within a small footprint. This results in a more compact design wh HDI printed circuit board ile maintaining high performance levels. One key advantage of HDI PCBs is their ability to support complex designs with smaller form factors.

When i PCB supplier t comes to using an HDI PCB, careful consideration must be given to Design For Manu HDI PCB facturability (DFM) Analysis. This process ensures that the board can be produced efficiently without sacrificing quality or reliability. Mul DFM Analysis tilayer PCB configurations are common in HDI designs, providing increased functionality while reducing overall size.

When selecting an HDI PCB su

pplier, it is crucial to choose a trusted partner with proven experience in manufacturing high-quality boards. Consideration should also be given to factors such as lead times, pricing, and technical support c HDI PCB apabilities.

In conclusion, HDI PCBs offer unparalleled benefits for modern electronics applications whe

re space constraints and performance demands are critical. By understanding the manufacturing processes, characteristics, advantages, usage methods, and considerations for choosing this product type wisely will ens

ure successful integration into your next electronic device project.