Title: The Ultimate Guide to Waterproof Solde waterproof solder wire connectors r Wire Connectors

Waterproof solder wire connectors are essential components in various industries where preventing water damage is crucial. These connectors are designed to provide a secure and reliable connection while protecting against moisture, liquids, and immersion. In this article, we will explore the manufacturing process, features, advantages, usage methods, how to choose the right product, and conclude with valuable insights.

Manufacturing Process: Moisture-proof soldered wire connectors

Waterproof solder wire connectors are typically made using high-quality materials such as silicone or polyethylene. The manufacturing process involves molding the connector housing to ensure a tight seal against water ingress. The solder connections inside the connector are also treated with special coating

s to prevent corrosion and maintain conductivity even in wet conditions.

Features:

Moisture-proof soldered wire connecto waterproof wiring connectors rs offer excellent protection against humidity and damp environments. Liquid-tight soldered wire connectors provide a secure seal that prevents liquid penetration into the wires. Waterproof soldered wire connectors can withstand exposure to water without compromising pe waterproof connector manufacturer rformance. Immersion-proof soldered wire connectors go above and beyond by ensuring full submersion resistance for underwater applications.

Advantages:

The main advantage of waterproof solder wire connectors i Liquid-tight soldered wire connectors s their ability to maintain a reliable electrical connection in harsh environmental conditions. Whether it’s outdoor installations exposed to rain or marine applications facing constant moisture, these connectors ensure uninterrupted power supply and signal transmission.

Usage Methods:

When using waterproof solder wire connectors, it is important to follow proper installation procedures. Start by stripping the wires’ insulation and tinning them before inserting them into the connector Waterproof soldered wire connectors terminals. Apply heat using a soldering iron to

melt the solder and create a secure bond between the wires and connector pins.

How to Choose the Right Product:

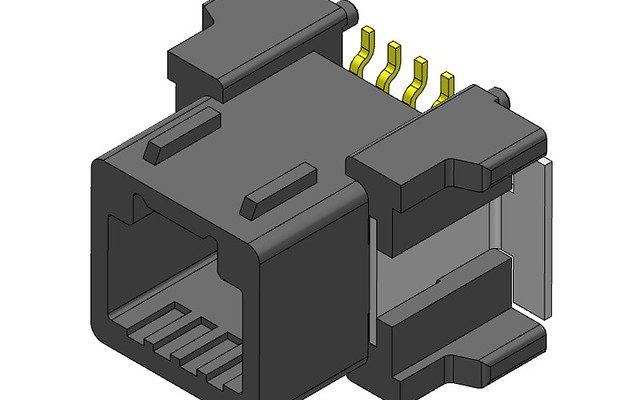

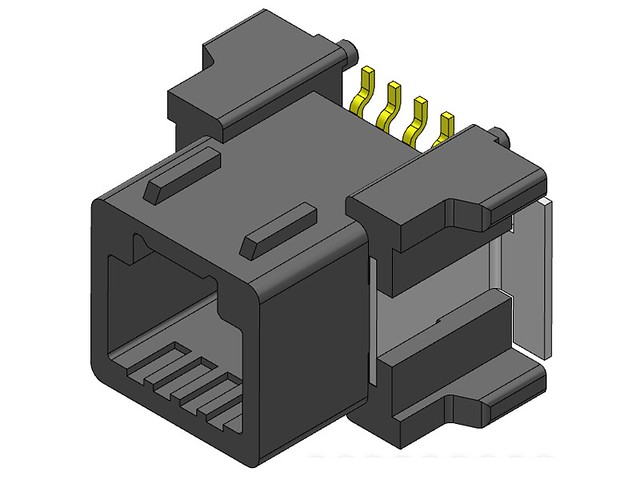

When selecting waterproof solder wire connectors for your project, consider factors such as IP rating (Ingress Protection), cable siz rj45 waterproof connector e compatibility, temperature range tolerance, and application requirements. Look for reputable manufacturers like waterproof connector manufacturer who specialize in producing high-quality products with certifications for reliability.

Conclusion:

In conclus waterproof solder wire connectors ion,

waterproof

solder

wire

connectors.

Can offer robust protection.

Against moisture

and liquids,

Making them ideal

for various industries.

It’s essential

to choose carefully,

based on your specific needs.

By following these guidelines,

you can effectively utilize waterproof soldersWireConnectors Connect over only Ensuring Reliable connections But Also Long-lasting Durability keeps critical Systems running smoothly Now You have comprehensive understandingOfWaterProofSoldiersWieConnectOrs And How To Best Utilize waterproof solder wire connectors Them For Your Next Project