Wa Water-resistant soldered wire connectors terproof solder wire connectors are essential components for various electronic and electrical applications. These connectors play a crucial role in ensuring the safety and efficiency of electrical connections in environments where exposure to water or moisture is a concern.

Manufacturing Pr waterproof wiring connectors ocess:

Waterproof solder wire connectors are typically made using high-quality materials such as silicone or rubber. These materials provide excellent insulation properties, preventing water from penetrating waterproof solder wire connectors the connector and causing damage to the wires inside. The manufacturing process involves molding the materials into a durable and watertight casing that can withstand harsh environmental conditions.

Features:

– Immersion-proof soldered wire connectors

– Water-resistant soldered wire connectors

–

Rainproof soldered wire connectors

– Moisture-proof soldered wire connectors

– Liquid-tight soldered wire connecters

The key feature of waterproof solder wire connectors is their ability to resist water infiltration, making them ideal waterproof solder wire connectors for outdoor applications or areas with high humidity levels. These connectors provide a secure and reliable connection that minimizes the risk of electrical malfunctions due to moisture exposure.

Advantages:

The advantages of waterproof solder wire connectors include:

1. Protection against water damage.

2. Long-lasting durability.

3. Easy installation process.

4. Reliable performance in various weather conditions.

5. Versatility for use in different applica waterproof connector manufacturer tions.

Usage Method:

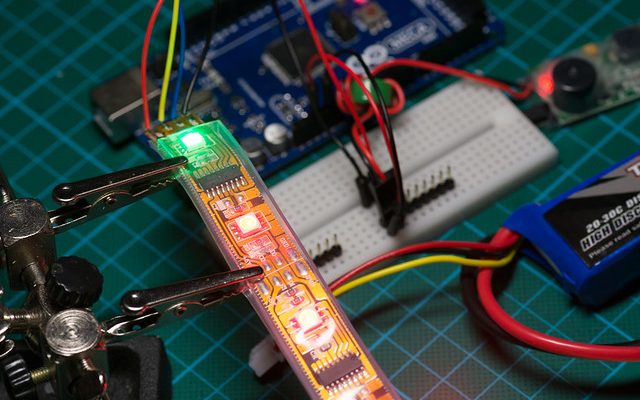

To use waterproof solder wire connectors, simply strip off the insulation from the wires, insert them into the connector terminals, and apply heat using a soldering iron to create a secure bond between the wire rj45 waterproof connector s and connector pins. Ensure that all connections are properly sealed with heat shrink tubing for added protection against moisture ingress.

How to Select This Product:

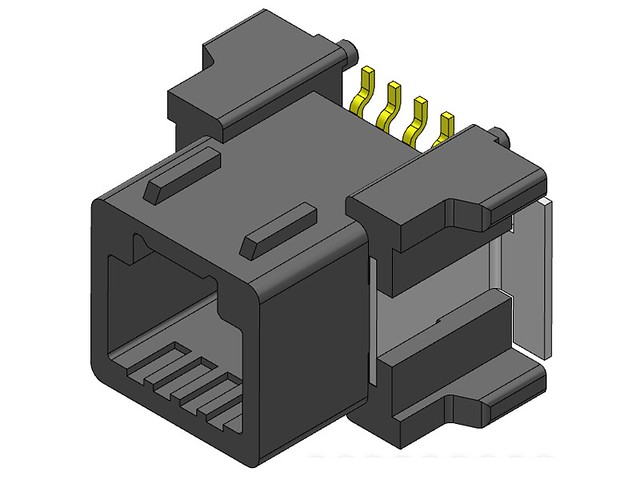

When selecting waterproof solder wire connectors, co waterproof solder wire connectors nsider factors such as compatibility with your specific application requirements, IP rating for water resistance level, number of terminals needed, and current-carrying capacity of the connector. Choose reputable manufacturers like RJ Rainproof soldered wire connectors 45 Waterproof Connector Manufacturer for quality assurance.

Conclusion:

In conclusion, waterproof solder wire connectors offer an effective solution for protecting electrical connections from water damage in ch Immersion-proof soldered wire connectors allenging environments. By understanding their manufacturing process, features, advantages, usage methods, and selection criteria outlined above,you can confidently choose the right product tailored to your needs.