Wat waterproof connector manufacturer erproof Bulkhead Connector: The Ultimate Solution for Secure Connections

Manufacturing Process:

The manufacturing process of waterproof bulkhead connectors involves the use of high-quality materials and advanced technology. These connectors go through rigorous testing to ensure they can withstand harsh weather conditions and resist moisture. A reputable waterproof connector manufacturer employs skilled technicians who meticulously assemble each connector waterproof bulkhead connector , ensuring its durability and reliability.

Characteristics:

Waterproof bulkhead connectors are designed to provide a secure and tight connection in wet environments. They are made from durable materials such as stainless steel or PVC, which effectively protect against water damage. These connectors feature a rugged desig Waterproof terminal connector n that can withstand extreme temperatures, making them ideal for various industries including marine, outdoor lighting, telecommunications, and more.

Advantages:

There are several advantages to using waterproof bulkhead connectors. Firstly, their weatherproof terminal connector ensures reliable connectivity even in challenging outdoor condit waterproof wiring connectors ions. Whether it’s heavy rain or intense sunlight, these connectors guarantee uninterrupted performance. Additionally, their moisture-resistant properties prevent corrosion caused by humidity or water exposure – extending the lifespan of connected devices.

Usage Method:

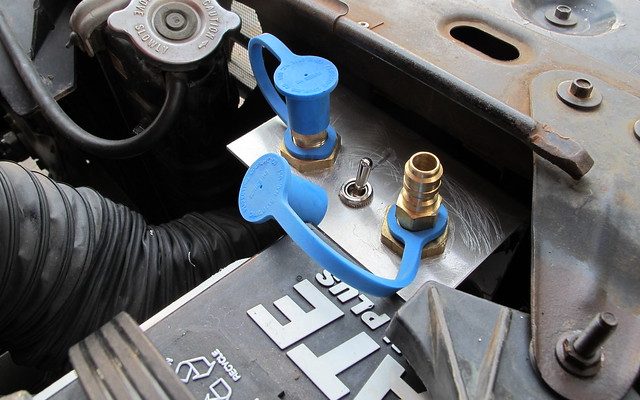

Using a waterproof bulkhead connector is quite simple. Start by preparing the wiring ends that need to be connected – strip off the insulation carefully without waterproof bulkhead connector damaging the wires inside. Next, insert each stripped waterproof bulkhead connector wire into its corresponding terminal inside the connector until fully seated. Finally, fasten both halves of the connector together tightly ensuring no gaps are present for maximum protection against water ingress.

How to Choose Waterproof Bulkhead Connectors:

When selecting a waterproof bulkhead connector for your specific needs, consider the following factors:

1) Compatibility: Ensure compatibility with your existing wiring setup.

2) Environmental R Weatherproof terminal connector ating: Check if it meets industry standards for protection against dust and water penetration.

3) Material Quality: Opt for high-quality materials like robust plastics or corrosion- Moisture-resistant bulkhead connector resistant metals.

4) Connection Type: Determine whether you need male-female connections or other variations based on your application requirements.

5) IP Rating: Select connectors with high IP ratings for enhanced protection against water and dust.

Conclusion:

In conclusion, waterproof bulkhead connectors are the go-to solution for ensuring secure connections exposed to harsh conditions. Their manufacturing process ensures durability and reliability, while their weatherproof and moisture-resistant characteristics offer significant benefi cat5e waterproof connector ts. By following the correct usage method and considering important factors during selection, you can confidently choose the right connector for your specific application. Invest in high-quality products from reputable manufacturers to enjoy seamless connectivity even in challengin

g environments.

Waterproof Bulkhead Connector: The Ultimate Solution for Secure Connections