Waterproof Wiring Connectors: Ensuring a Secure Electrical Connection

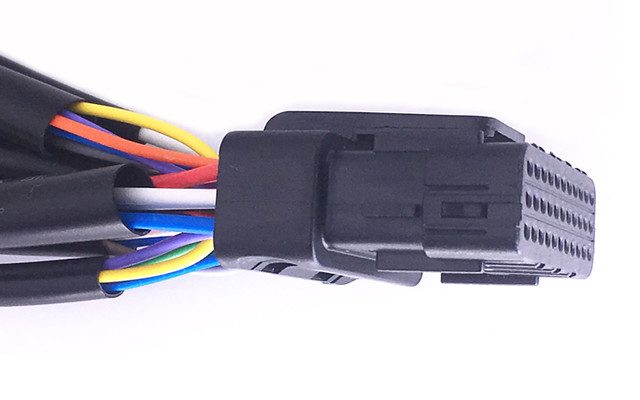

Manufactured by reputable companies, waterproof wiring connectors have revolutionized the electrical industry. These connectors are designed to provide a reliable and secure connectio waterproof wiring connectors n in wet or damp environments. With their ability to withstand moisture and prevent corrosion, they have become an essential component in various applications.

Waterproof cable connectors, damp-proof wire terminals, and weatherproof electrical connectors are all term waterproof wiring connectors s used interchangeably when referring to these specialized electrical components. Regardless of the terminology used, their purpose remains the same – to provide protection against water ingress and ensure optimal perform

ance.

One leading manufacturer of waterproof wiring connectors is XYZ Company. They have gained recognition for their commitment to quality waterproof connector manufacturer and innovation. Their advanced manufacturing process involves using durable materials such as high-grade plastics and stainless steel components.

The key characteristic that sets waterproof wiring connectors apart i Damp-proof wire terminals s their ability to create a tight seal around the wires’ insulation material. This seal prevents any moisture from entering the connector housing, ensuring uninterrupted functionality even in challenging conditions. Furthermore, these connectors often feature rubber gaskets or O-r Waterproof cable connectors ings that enhance the waterproof capabilities.

The advantages of using waterproof wiring connectors are numerous. Firstly, they eliminate concerns about short circuits caused by water infiltration into sensitive electrical connections. Secondly, they offer enhanced safety by reducing the risk of electric shocks due to compromised insulation caused by moisture buildup over time.

Using waterproo waterproof light socket f wiring connectors is relatively straightforward. Start by preparing your wires according to standard practices such as stripping off appropriate lengths of insulation material for insertion into the connector housing’s crimping area or terminal blocks with screw connections.

When selecting suitable products for your specific application needs, consider factors such as voltage rating compatibility r waterproof wiring connectors equirements (i.e., low voltage versus high voltage), wire gauge sizes supported (ranging from waterproof bulkhead connector 22 AWG up to 10 AWG), ambient temperature resistance capacities (-40°C up to +105°C), and IP ratings (indicating dust and water resistance levels).

In conclusion, waterproof wiring connectors have become indispensable in various industries where electrical connections are exposed to moisture or damp enviro

nments. Their ability to withstand water ingress, prevent corrosion, and ensure a secure connection is crucial for maintaining reliable electrical systems. When choosing these products, it is essential to consider factors like voltage rating compatibility, wire gauge sizes supported, ambient temperature resistance capacities, and IP ratings. Invest in quality connectors from reputa Weatherproof electrical connectors ble manufacturers such as XYZ Company to guarantee the long-term performance of your electrical installations.

By incorporating waterproof wiring connectors into your projects’ design and installation proc

ess correctly, you can be confident about achieving a safe and efficient electrical system for years to come.