Title: The Ultimate Guide to Waterproof Solder Wire Connectors

Waterproof solder wire connectors are essential componen Water-resistant soldered wire connectors ts in electrical systems that require protection from moisture and water. These connectors are designed to provide a secure and reliable connection while also keeping out water, preventing corrosion and potential short circuits.

Manufacturing Process:

Waterproof solder wire connectors are typ

ically made using high-quality materials such as silicone or rubber seals that create a tight barrier against water infiltration. The soldering process involves joining the wires together secur waterproof solder wire connectors ely, ensuring a strong electrical connection.

Features:

– Water-resistant soldered wire connectors offer excellent protection against moisture intrusion.

– Sealed soldered wire connectors prevent corrosion and damage caused by expo waterproof wiring connectors sure to water.

– Moisture-proof soldered wire connectors ensure long-lasting performance in wet environments.

– Rainproof soldered wire connectors can withstand heavy rain and outdoor conditions without compromising functionality.

Advantages:

The main advantage of waterproof solder wire connecto

rs is their ability to maintain a reliable electrical connection even in challenging environmental conditions. They help prevent costly downtime and repairs due to water-related damage Sealed soldered wire connectors , making them ideal for outdoor applications or areas prone to moisture exposure.

Usage:

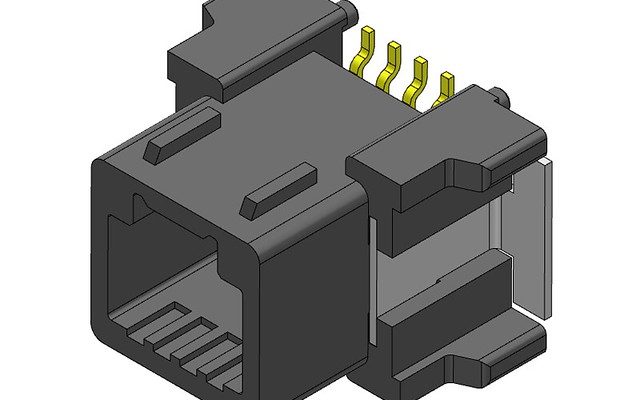

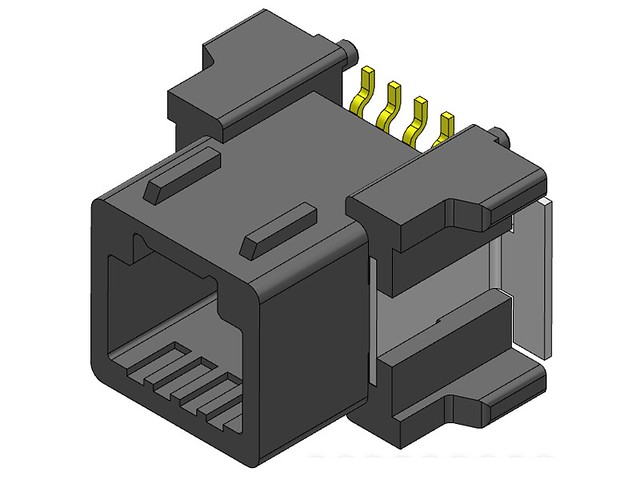

To use waterproof solder wire connectors, simp waterproof solder wire connectors ly strip the insulated coating from the wires, twist them together tightly, insert them into the connector housing, and apply heat using a soldering iron until the connection is secure. Ensure that the seal is properly closed to guarantee full waterpro rj45 waterproof connector ofing protection.

How to Choose This Product:

When selecting waterproof solder wire connectors, consider factors such as IP rating (protection against solids and liquids), compatible wire gauge sizes, voltage rating, temperature range, and application requirements. Look for reputab Moisture-proof soldered wire connectors le manufacturers like RJ45 Waterproof Connector Manufacturer who offer quality products with proven reliabili waterproof solder wire connectors ty.

Conclusion:

In conclusion,

waterproof

solder

wire

connectors play a crucial role in maintaining safe and efficient electrical connections in moist or wet environments. By investing in high-quality sealed

connectors,

users can protect their wiring systems from corrosion,

short circuits,

and other issues associated with water exposure.Endeavorto choose certified products from trusted manufacturers for optimal performance andreliabili waterproof connector manufacturer ty..