Title: The Ultimate Guide to Waterproof Solder Wire Connectors

Waterproof solder wir waterproof connector manufacturer e connectors are essential components in various industries where moisture and water exposure are common. These connectors play a crucial role in ensur Water-resistant soldered wire connectors ing the longevity and reliability of electrical connections, especially in outdoor or harsh environments.

Manufacturing Process:

Waterproof solder wire connectors are typically made using high-quality materials such as heat-shrink tubing, solder, and sealing adhesive. The wires are first stripped and tinned before being waterproof solder wire connectors inserted into the connector. A heat source is then applied to melt the solder, creating a secure bond between the wires.

Char

acteristics:

Sealed soldered wire connectors offer protection against water ingress by forming a tight seal around the connection point. Water-resistant variants provide added protect waterproof solder wire connectors ion against splashes and light rain. Waterproof models take it a step further by offering complete immersion-proof capabilities.

Advantages:

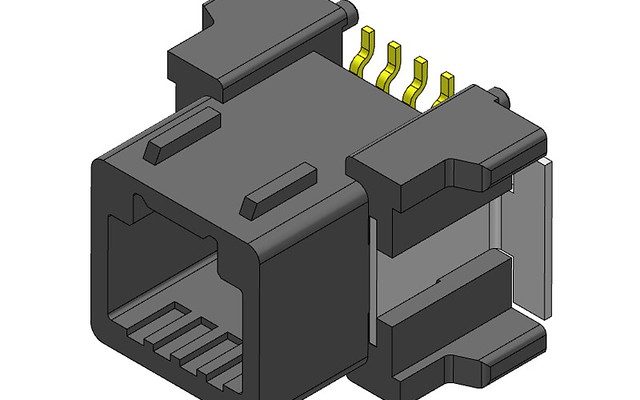

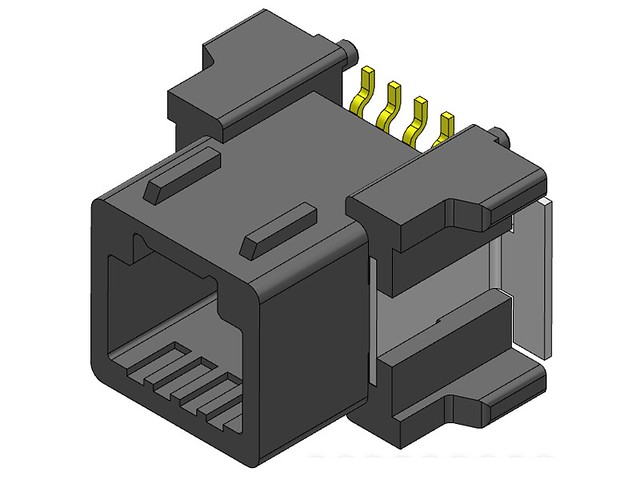

The main advantage of waterproof solder wire connectors is their ability to prevent corrosion and short circuits caused by moisture expo Waterproof soldered wire connectors sure. They also ensur rj45 waterproof connector e stable electrical conductivity even in humid or wet conditions.

How to Use:

To use waterproof solder wire connectors, simply strip the wires to an appropriate length, insert them into the connector, apply heat evenly using a heat gun until the solder melts completely, and allow it to cool for a secure connection.

Choosing the Right Product:

Wh

en selecting waterproof solder wire connectors, consider factors s Sealed soldered wire connectors uch as IP rating (Ingress Protection), compatibility with your specific application requirements, durability of materials used, and ease of installation.

Conclusion:

In conclusion, waterproof solder wire connectors are indispensable for maintaining reliable electrical connections in challenging environmental conditions. B waterproof wiring connectors y understanding their manufacturing process, characteristic waterproof solder wire connectors s, advantages,

and proper usage methods outlined above,you can confidently choose suitable products that meet your needs for long-lasting performance.