Title: The Ultimate Guide to HDI PCBs

High-Density Interstitial Copper-Embedded PCB, also known as HDI PCB, is a type of printed circuit board that offers many advantages in terms of desig PCB supplier n flexibility and performance. This advanced circuit board technology (ACBT) has gained popularity in various industries due to its unique f Complex Layered Printed Circuit Board (CLPCB) eatures and benefits.

Manufacturing Process:

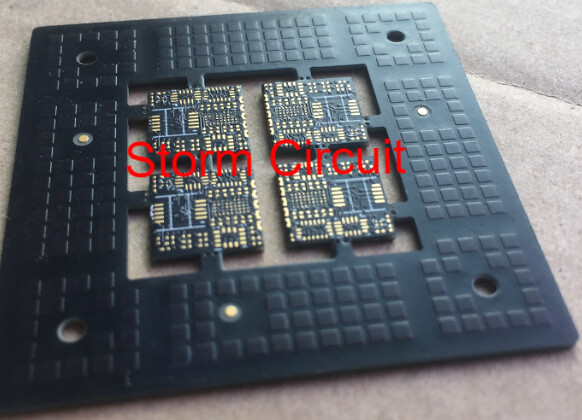

HDI PCBs are manufactured using a complex layered printed circuit board (CLPCB) technology that involves the incorporatio

n of microvias within the inner layers of the PCB. These microvias allow for higher component density and better signal integrity. The process also includes embedding copper within the substrate, which enhances thermal conductivity and electrical performance.

Characteristics:

One of the key features of HDI PCBs is their high-density interconnect capability, which allows for more components t High-density interstitial copper-embedded PCB o be placed on a smaller area. This makes them ideal for applications where space is limited bu DFM Analysis t performance is crucial. Additionally, HDI PCBs have thinner traces and spaces, leading to improved impedance control and signal quality.

Advantages:

HDI PCBs offer several advantages over traditional multilayer PCBs. They provide better electrical performance, reduced signal loss, inc HDI PCB reased reliability, and lower electromagnetic interference. Furthermore, these boards are lighter in weight and have a smaller form factor compared to standard PCBs.

Usage:

HDI PCBs are commonly used HDI PCB in devices such as smartphones, tablets, medical equipment, aerospace systems, automotive electronics, and more. Their compact size and high-performance capabilities make them Multilayer PCB perfect for applications that require fast data transmission speeds and reliable operation.

How to Select an HDI PCB Supplier:

When choosing an HDI PCB supplier, it’s essential to look for one with

expertise in DFM analysis (Design For Manufacturability). A reputable supplier should offer comprehensive design support services to ensure your product meets all specifications while minimizing costs and lead times.

Conclusion:

In conclusion,

HDI PCBS represent the future of electronic manufacturing with their advanced technology

in design.and performance.These versatile boards offer numerous benefits over

traditional alternatives

and can greatly enhance the functionality.of various electronic products.Choosinga reliable supplier

with knowledge indesignmanufacturingprocessesis criticaltosecuringhigh-qualityHDIP HDI PCB CBsthatmeet

your specific requirements.As technologycontinuesto advance,HDI PCBS will continue tonot on Microvia PCB ly meet.but exceedthe demands offutureelectronicapplications.

ChooseHDIPCBsandexperienceenhancedperformance.reliability,and versatilityinyournextproject!