Alloy Steel Plates: The Manufacturing Process, Characteristics, Advantages, Usage Methods and Selection Guidelines

Manufacturing Process:

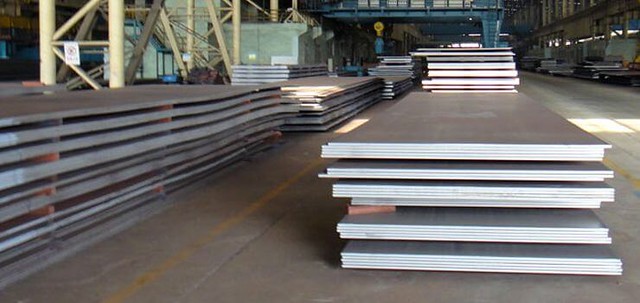

Alloy steel plates are manufactured through Alloy Sheet a series of processes that involve melting various elements together to form a homogeneous mixture. This mixture is then poured into molds and cooled to solidify it into the desired shape. The alloying elements add strength, hardness, and resistance to Steel alloy panel corrosion or wear to the final product.

Characteristics:

Alloy steel plates possess several important characteristics that make them highly desirable in many industries. Firstly, they exhibit excellent mechanical properties such as high tensile strength and toughness. This makes them suitable for applications requiring heavy-duty use under extreme conditions. Secondly, they have superior heat resist Alloy steel sheet ance and can withstand elevated temperatures without deformation or degradation. Lastly, alloy steel plates are known for their exceptional corrosion resistance due to the presence of specific alloying elements.

Advantages:

The advantages offered by alloy steel plates are numerous. F alloy steel plate irstly, their enhanced mechanical properties increase overall product durability and longevity compared to standard carbon steels. This makes them ideal for demanding applications in sectors like construction, manufacturing equipment production, and shipbuilding industries where structural integrity is paramount.

Secondly,

due

to

their

excellent

heat-resistant

properties,

alloy

steel

plates find extensive use in petrochemical plants,

power generation faci

lities,

and various high-temperature environments.

Moreover,

the enhanced corrosion resistance reduces maintenance needs while ensuring prolonged service life even when exposed to corrosive substances,

such as chemicals or moisture.

Additionally,

these

plates also provide improved weldability,

enabling easier fabrication during construction or repair works.

Usage Methods:

Alloy steel plate alloy steel plate s are utilized in diverse applications across multiple industries because of their unique combination of properties.

In the automotive industry,

they serve as vital components in building robust chassis structures with higher crash energy absorption capabilities.

Similarly,

in aerospace engineering,

the lightweight yet strong nature of these plates allows for the construction of fuel-efficient aircraft,

while maintaining structural integrity in extreme conditions.

Moreover,

in oil and gas exploration,

alloy alloy steel plate steel plates are utilized to fabricate pipelines that can withstand high-pressure environments without compromising safety.

How to Select Alloy Steel Plates:

Choosing the appropriate alloy steel plate involves considering several factors. Firstly, it is crucial to identify the specific requirements of the intended application, such as mechanical strength, heat resistanc alloy steel plate e, or corrosion resistance. Secondly, one should assess the available options based on standards and certifications provided by reputable manufacturers. Additionally, consulting industry experts or conducting thorough research aids in selecting alloys with optimal compositions that meet Compound alloy panel desired performance criteria. Furthermore, evaluating cost considerations and availability also play a vital role in making an informed decision.

Conclusion:

Alloy steel plates are essential components used across various industries due to their exceptional mechanical properties, heat resistance, and corrosion resistance. Their manufacturing process ensures quality through controlled mixing and solidification techniques. The advantages offered by these plates include increased durability under harsh conditions a Alloy Sheet nd improved weldability during fabrication processes. Knowing how to choose the right alloy steel plate enhances suitability for specific applications while ensuring cost-effectiveness. In conclusion, investing in high-quality alloy steel plates guarantees long-lasting performance and reliability for critical infrastructure components or equipment requiring superior st

rength and resilience.