Ceramic PCBs: Providing High Temperature and Heat Dissipation Solutions

Introduction

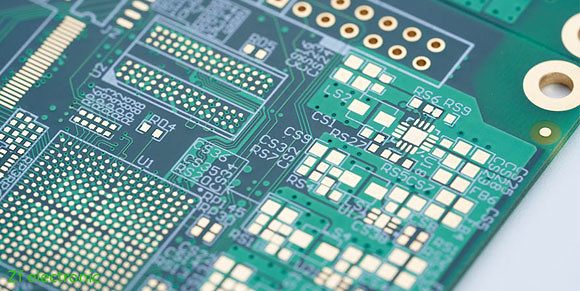

In today’s advanced technology world, the demand for effi High temperature PCB cient and reliable circuit boards is constantly increasing. The need for high temperature resistance and excellent heat dissipation capabilities has given rise to a new type of printed circuit board – Ceramic PCB. This article aims to explore the manufacturing process, features, advantages, applications, selection criteria, and conclude with the significance of Ceramic PCBs in various industries.

Manufa

cturing Process

Ceramic PCBs are manufactured using advanced techniques that involve intricate processes. The ceramic-based materials undergo precision drilling, deposition of conductive traces or vias on multiple layers through thin-film metallization, followed by laminating under controlled pressure and temper C-PCB (abbreviation for ceramic PCB) ature conditions. Specialized equipment is used to ensure accurate alignment during production.

Features

• High Temperature Resistance: Ceramic PCBs can withstand extreme temperatures without compromising their performance or reliability.

• Heat Dissipation Capability: Due to their unique composition and design, Ceramic PCBs excel a Ceramic PCB t dissipating heat effectively from electronic components.

• Miniature Size: These boards can be fabricated in small sizes with high density interconnect (HDI) technology.

Advantages

1. Enhanced Reliability: Ceramic-based materials offer better stability even when exposed to thermal stress cycles than traditional circuit board substrates like FR4.

2. Improved Performance: The excellent thermal conductivity of ceramic materials ensures enhanced signal integrity and reduces Ceramic PCB electromagnetic interference (EMI).

3. Space Optimization: As they support compact HDI designs due to finer trace widths and spacing requirements compared to other types of substrates.

4. Increased Longevity: The outstanding mechanical strength inherent in ceramic results in longer lifespan compared to alternative solutions.

Applications

The use cases for Ceramic PCBs are extensive across various industries including:

1 HDI PCB . Aerospace & Defense Sector – Missile guidance systems require robust circuits capable of operating at high temperatures while withstanding shocks and vibrations.

2. Automotiv Ceramic PCB e Sector – Ceramic PCBs are ideal for engine control modules, transmission systems, and battery management units.

3. High Power Electronics – Renewable energy sources such as solar panels or wind turbines benefit from the ceramic substrate’s ability to handle high currents without overheating.

4. Telecommunications – Base stations that require long-term reliability and resistance against harsh weather conditions can utilize Ceramic PCBs.

Selection Criteria

When selecting a Ceramics PCB, consider the following Heat dissipation circuit board factors:

1. Temperature Range: Ensure compatibility with your application’s temperature requirements.

2. Thermal Conductivity: Evaluate if the board possesses adequate thermal conductivity for efficient heat dissipation.

3. Material Properties: Look for ceramic materials that exhibit excellent mechanical strength, electrical insulation properties, and chemical stability.

Conclusion

Ceramic PCBs h HDI PCB ave emerged as an effective solution in scenarios where traditional circuit boards fail due to high temperature challenges or inadequate heat dissipation capabilities. Their unique manufacturing process ensures outstanding attributes like high temperature resistance, impro Ceramic PCB ved heat dissipation efficiency while maintaining compactness through HDI technology. By considering crucial selection criteria such as temperature range and material properties during procurement decisions, industries can harness the full potential of Ceramic PCBs for enhanced performance and longevity in their applications.